Novel robotic solution makes solar power more efficient

When you picture a solar power plant, the most prominent feature in your mind’s eye is probably a massive array of solar panels glinting in the sun. As a result, you might assume that those glossy panels make up the largest share of the plant’s cost. You’d be wrong.

Wasiq Bokhari, founder and CEO of a company called Qbotix that is using robotics to increase efficiency in the solar industry, says that despite their size, the panels are only about a third of the cost.

In a typical ground-mounted solar power plant, another 10 percent of the cost goes to inverters, 10 percent to electrical parts, 16-20 percent to a mounting system and 17-20 percent to labor. Qbotix focuses on the largest chunk of that pie — the mounting system and the labor — which at close to 40 percent make up a larger share of the cost than the solar panels themselves.

In addition, the Qbotix robotic system aims to actually increase the production of the plant by 35 to 40 percent over a typical fixed-mount system. That means revenues are higher by 35 to 40 percent and, ultimately, that the cost of electricity generated by the plant is lower.

How it works

There are three traditional ways to install solar panels on the ground. One is called fixed mount, which has a fixed orientation. Another is called a single-axis tracker, which can rotate from East to West throughout the day. The third is called a dual-axis tracker, which allows the panel to follow the sun like a sunflower.

Typically, a single-axis tracker produces about 20 percent more energy than a fixed-mount system and a dual-axis tracker produces about 40 percent more. The problem is that a dual-axis tracker can also cost twice as much, negating the savings.

There are several reasons for the additional cost in a dual-axis system. For the system to work, each of the posts that hold up the panels requires two high-quality motors. Subsequently, in order to minimize the cost per square meter, the arrays on each post are typically very large — sometimes as large as a tennis court. Building large structures outfitted with costly motors gets expensive, not to mention difficult to install.

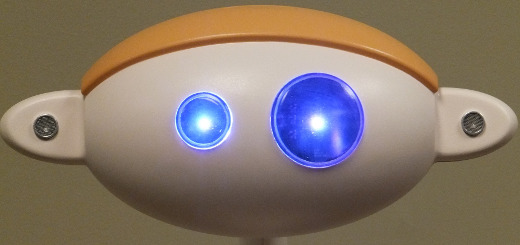

Qbotix’s innovation came when Bokhari realized that instead of putting motors on each post, he could build a single robot to take over the job.

“In essence what we’ve done is, instead of putting a pair of motors on every post, our motors drive themselves on a monorail from one post to the next,” he says.

For redundancy purposes, the distributed controller system actually uses two robots. The QBotix R-225, the company’s latest robot, can manage 340 kilowatts worth of solar panel, displacing hundreds of independent stationary motors. A solar field producing a megawatt of power would only need six robots: three “live” robots and three backups.

Since motors are no longer needed on each post, Qbotix can build trackers — the mounts on which the solar panels sit —that are smaller (about a tenth the size of a traditional system) and are purely mechanical. The robots can also collect a variety of data that allows the plant to grow smarter and optimize over time.

The robots orient the panels roughly every 40 minutes, which provides the efficiency required at a significantly reduced cost. The company’s pitch is that customers can achieve their overall energy production target with as much as 20 percent reduction in power plant cost.

“Since the solar industry is such a competitive industry that is a big deal,” he says.

Industry reaction

The biggest challenge for a new company like Qbotix, which was founded in 2010, has been convincing the people who finance solar projects that the system can produce efficiently over the course of 20 or 25 years without a track record to point to.

“The initial reaction was, ‘That’s a very neat idea. Do the economics work?'” says Bokhari.

To demonstrate that the efficiency they tout is actually real, Qbotix has set up five sites operating across the world — three in the U.S. and two in Japan. The locations include a desert site, a site that gets a lot of rain and more temperate locations.

“What you have to do is actually install systems and let them operate in different conditions for a reasonable amount of time so that it is apparent that there is no degradation of performance and that the system is robust,” he says.

The value of robotics

Solar power is currently a $70 billion dollar global industry, and it is growing at 10 percent annually, according to Bokhari. At the same time, price is coming down to where it can compete with other forms of energy. Amid this rapid growth, Bokhari says robotics have a part to play.

Currently, robotics are used in the installation of solar power plants as well as for cleaning solar power panels.

In the future, Bokhari thinks they can do more. For example, a typical power plant has people who walk around to ensure everything is working. Qbotix thinks all of that can be completely performed by robots operating autonomously.

Bokhari also points out that the demands of a solar power plant breed a particular type of robot. Because they’re usually located in remote areas with extreme conditions, they require a robot that is rugged and reliable, with a long lifetime and very little maintenance required. He says robots like those can be useful in other harsh environments, such as mining.

Solving a problem

Qbotix is privately held and employs about 40 people in Menlo Park, Calif. Investors including NEA, Firelake Capital, Siemens Venture Capital and Draper Nexus have put about $12.5 million into the company, which also received a $1 million research grant from the Department of Energy’s SunShot initiative.

It is Bokhari’s fourth company, but not his first in the solar industry. One of his previous ventures built solar farms, which made him very familiar with the challenges the industry faced. He didn’t start out as a roboticist, but he recognized that robotics offered the solution to an underlying business problem.

“My background is as an entrepreneur,” he said. “In the end, I don’t care if I use robotics or not, it just so happens that robotics gives us a very innovative, novel and also a very financially viable solution to an existing business problem.”

[ photo courtesy of Qbotix ]